[vc_row][vc_column][vc_video link=”https://youtu.be/WYnGRabmuU8″][vc_column_text]Description

Coffee are freeze-dried by freeze dryer gently, the water of coffee is extrat in the form of vapour during high-pressure vacuum production process.

The vapour is colleted on a condenser in the drying chamber, and returns to ice and is removed. All remaining “bound ” moisture will be extracted from pet food with increasing temperature. The physical structure and 99% nutritions of coffee will be maintained , and can be preserved for a long time.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Freeze dried coffee VS Spraying coffee” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1689646140806{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Freeze dried coffee VS Spraying coffee” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1689646140806{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Freeze drying highlights” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1682061453481{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]1. Maintaining the freshness of coffee: Freeze-dried coffee is made by freeze-drying coffee at low temperatures, this method can effectively maintain the freshness and flavor of coffee, as the freezing process can prevent oxidation and degradation.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Freeze drying highlights” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1682061453481{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]1. Maintaining the freshness of coffee: Freeze-dried coffee is made by freeze-drying coffee at low temperatures, this method can effectively maintain the freshness and flavor of coffee, as the freezing process can prevent oxidation and degradation.

2. Convenient to carry and store: Freeze-dried coffee is usually sold in small packages, which is very convenient to carry and store. There is no need for refrigeration, so you can enjoy a fresh cup of coffee at any time of the day or night.

3. Long shelf life: Because freeze-dried coffee is dehydrated and has a very low moisture content, freeze-dried coffee can be stored for at least 5 years under vacuum packaging. In contrast, traditional ground coffee loses its freshness quickly when exposed to air and humidity.

4. Convenient brewing: Freeze-dried coffee usually exists in the form of instant coffee, which can be quickly brewed by adding hot water, with good rehydration. This is very convenient for busy people, without the need for cumbersome coffee brewing process.

5. Retain the nutrients of coffee: Freeze-dried coffee retains the nutrients in coffee, such as caffeine and antioxidants, during the production process. Therefore, freeze-dried coffee not only has the aroma and taste of coffee, but also provides some benefits to the body.

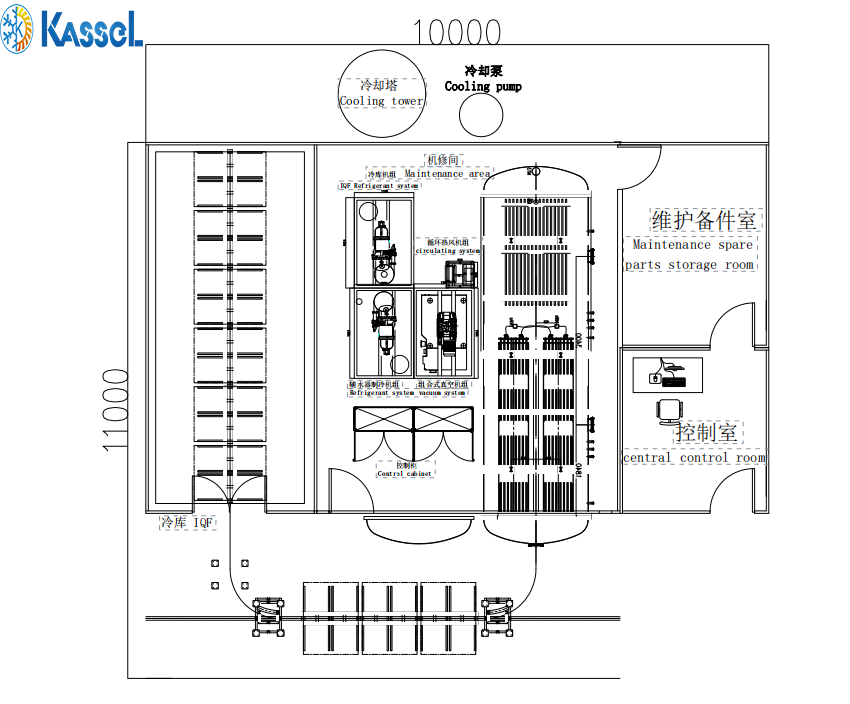

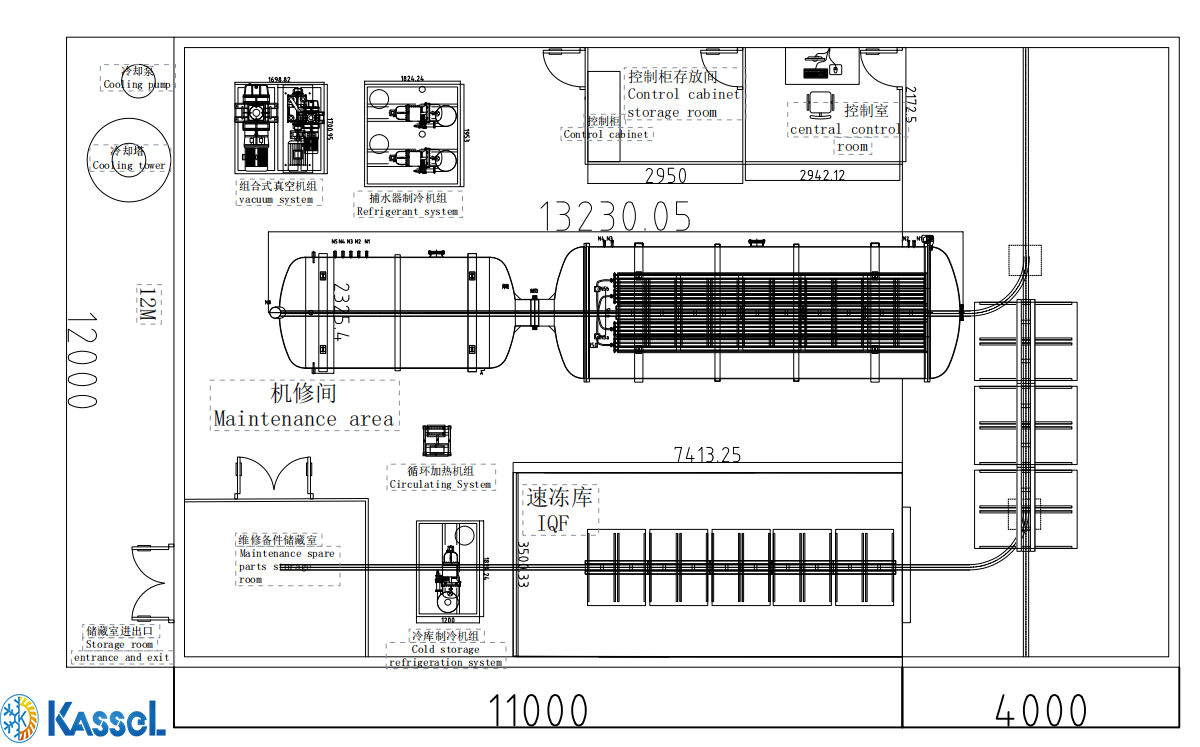

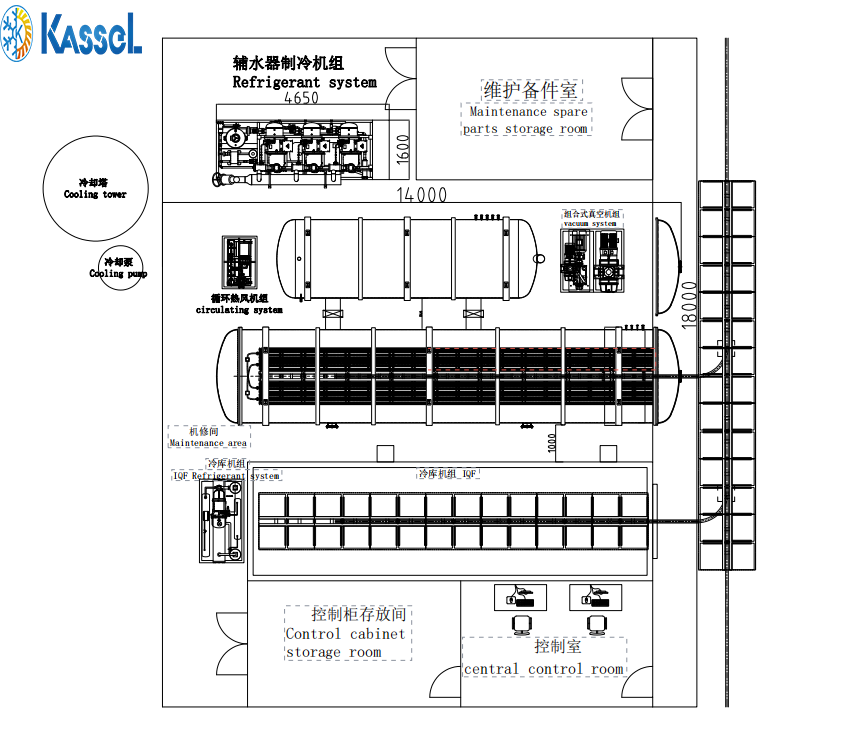

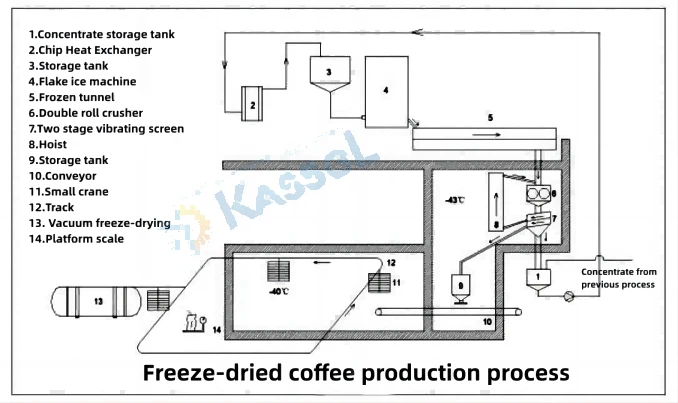

6. Reduce Waste: Since freeze-dried coffee can be kept for a long time without losing its freshness, coffee waste can be reduced. For coffee shops and coffee lovers, this is an important advantage.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Technical Specification” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681992318008{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_raw_html]JTVCd3BkYXRhdGFibGUlMjBpZCUzRDMlNUQ=[/vc_raw_html][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”The Whole Production Line” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969765308{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]1. Pre-treatment: screening, cleaning

2. Roasting

3. Grinding: to improve the extraction efficiency, the roasted coffee beans are ground into a certain particle size

4. Extraction: Under a certain temperature and pressure, the active ingredients are extracted into water

5. Concentration: through vacuum concentration, the concentration of coffee is increased at a lower temperature (i.e. the water is removed from the liquid coffee, which facilitates subsequent drying and increases production efficiency)

6. Drying: As the aromatic substances of coffee are very heat-sensitive, they are very volatile at higher drying temperatures (in fact, they are already volatile in the previous extraction and concentration processes), which is the main reason why instant coffee is often not as aromatic as fried and boiled coffee. But our vacuum freeze drying technology can solve this problem perfectly

Firstly, the coffee concentrate is frozen at a low temperature (-40°C), where the water is frozen into tiny ice crystals, and then slowly heated and sublimated under high vacuum conditions (the heating temperature will not exceed 35°C), through this low humidity drying method, the aromatic substances in the coffee (i.e. heat-sensitive substances) are well preserved, so the aroma of freeze-dried coffee is rich and pure.

7.Packing

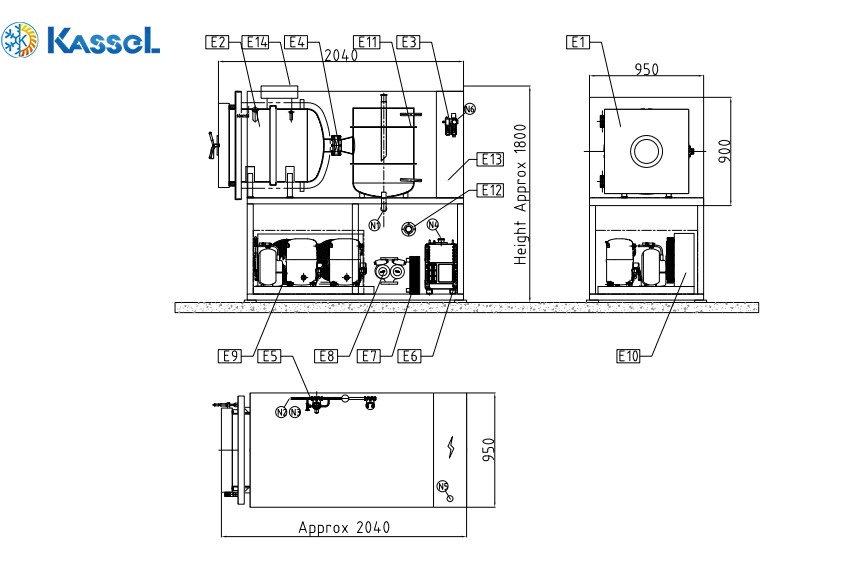

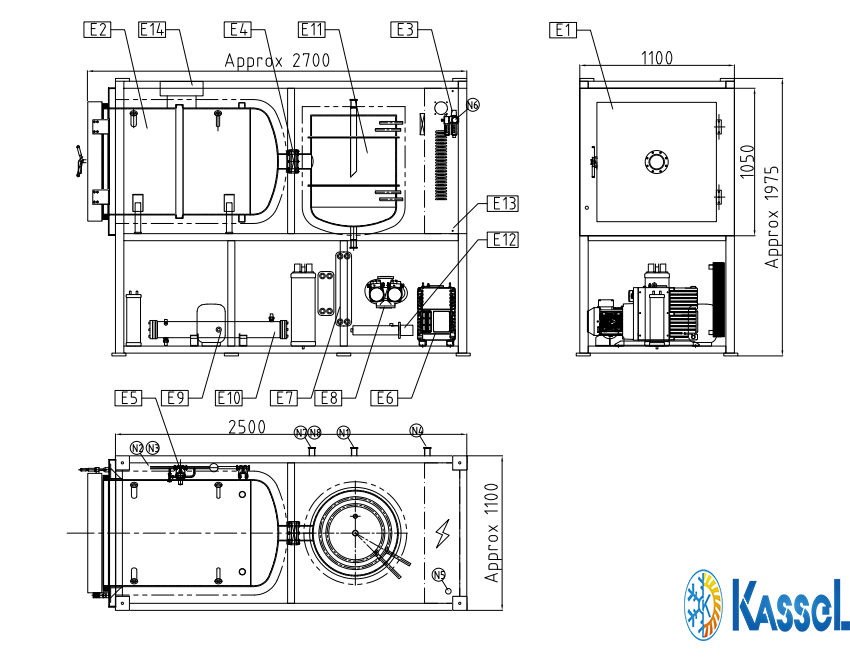

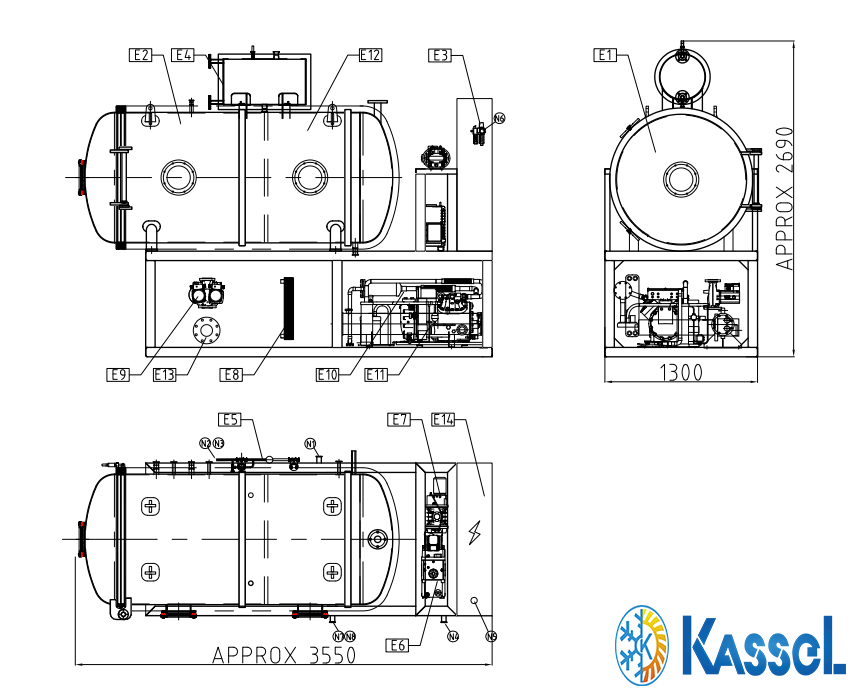

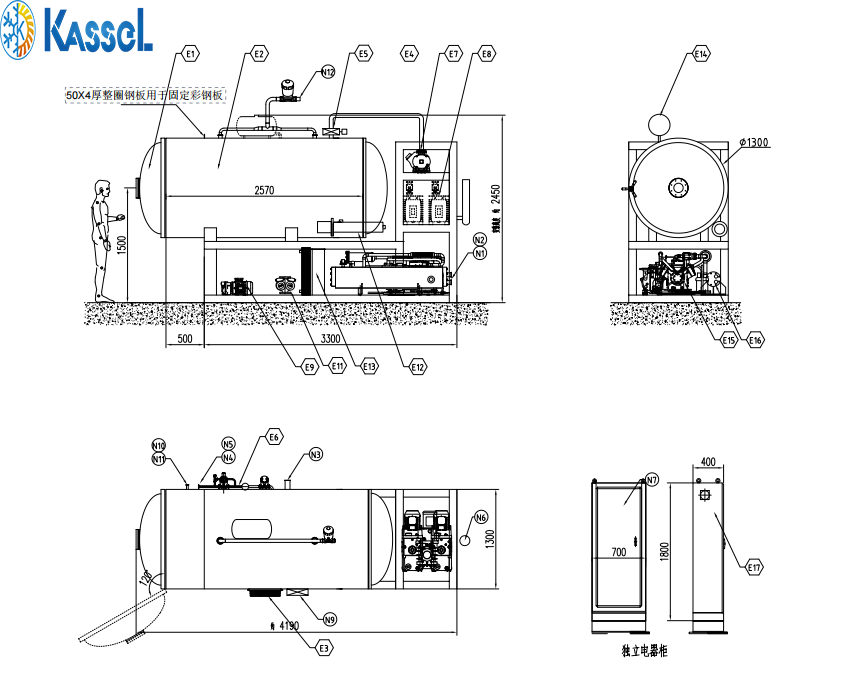

Kassel is a professional manufacturer and dedicated to provide our customers with R&D, production, selling& after-sales service as a turnkey solution with our customers.Our industrial freeze dryer (1㎡to 200㎡) are widely used in the food, pharmaceutical and cosmetic industries and have been widely recognised and praised for their efficient, stable and reliable performance.

Our lyophilisers are equipped with advanced technology and high quality materials, and feature highly efficient refrigeration systems, intelligent control systems and safe and reliable operating systems to meet the needs of different customers. We can also customise our machines according to customers’ special requirements to meet their individual needs.

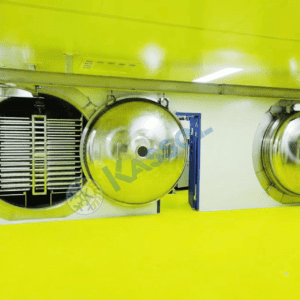

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Highlights And Features” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969791100{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]1. Aerospace grade aluminum alloy partition material, double-sided radiation heating, radiation rate of more than 90%, good temperature uniformity and thermal conductivity.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Highlights And Features” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969791100{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]1. Aerospace grade aluminum alloy partition material, double-sided radiation heating, radiation rate of more than 90%, good temperature uniformity and thermal conductivity.

2.High efficiency mixed refrigerant medium, low freezing point and high boiling point, high heat transfer efficiency, long service life

3.Patented gas diversion design and control technology, strong water capture ability, high drying efficiency.

4.Accurate sensor calibration function to ensure the accuracy of process parameters in long-term use.

5.The drying curve optimization control algorithm can control the heating rate and vacuum degree value of the products in the drying stage.

6.Bitzer compressor from germany, stable, reliable, no faluire.

7.Ulvac vacuum pump from japan, excellet performance ,no noise. good stability

8.Simens PLC control cabinet, safety, stable,effectiveness.

9.Perfect pre and after-sales service: providing instabllation, debugging,traing service etc

10.Pre-freezing and drying are two separated structures, which is able to freeze and dry at the same time. This can improve the efficiency of freeze-drying and product efficiency.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Successful Projects” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969204220{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Successful Projects” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969204220{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”FAQ” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969254779{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Why your price is relatively high?

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”FAQ” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969254779{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Why your price is relatively high?

We are in zhejiang province which is known for the quliaty of its mechanical manufacturing and fine craftsmanship. Our first priority is always based on the quality. If you want A more economica price,please let us know your budget, So that we could make some modification to meet your needs.

What is your installation service system?

Our enigneer has been working 20 years in freeze dryer machines and has been over to 20 countries to install our freeze dryer equipments. Now he has US Visa, So it is easy for him to go many other countries to start installation. So when we make a deal , we will arrange our engineer to your factory in 2 weeks, and he wil finish his work within 2 weeks. The customer should pay his round-trip ticket,hotel, food and daily wage USD100. Our engineer can speak english and can communicate with your team fluently . Excellent service deservces its cost.

What Is Your After-Sales Service System?

Our target customer groups are all from developed countries, USA, European, Middle east, Korea, Russia, Colomibia etc. They are all have high requirements with freeze-dryer. The core components of our freeze dryers are all imported from germany , Japan, Italy etc, has excellent stability , low energy consumption and almost no faluire. If there are any problems caused by non-human facors, we will undertake the full responsibility and relace new one for you, so please don’t worry about our after-sales service.

How Could You Control And Ensure Your Machine Quality?

Firstly of all, we are professional manufacturer and has own production line, the core components of freeze dryer are all imported from Germany, Japan,

Italy etc, and each part is completed independently by our factory self. We take the quality as priority and control the each production process strictly ,from design ,R&D, producing .We refuse to attract our customers with low price but low quality.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Send Inquiry” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1683357874324{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”]

[/vc_column][/vc_row]