[vc_row][vc_column][vc_video link=”https://youtu.be/pdnJwZb-rrA”][vc_column_text]

What is freeze dryer?

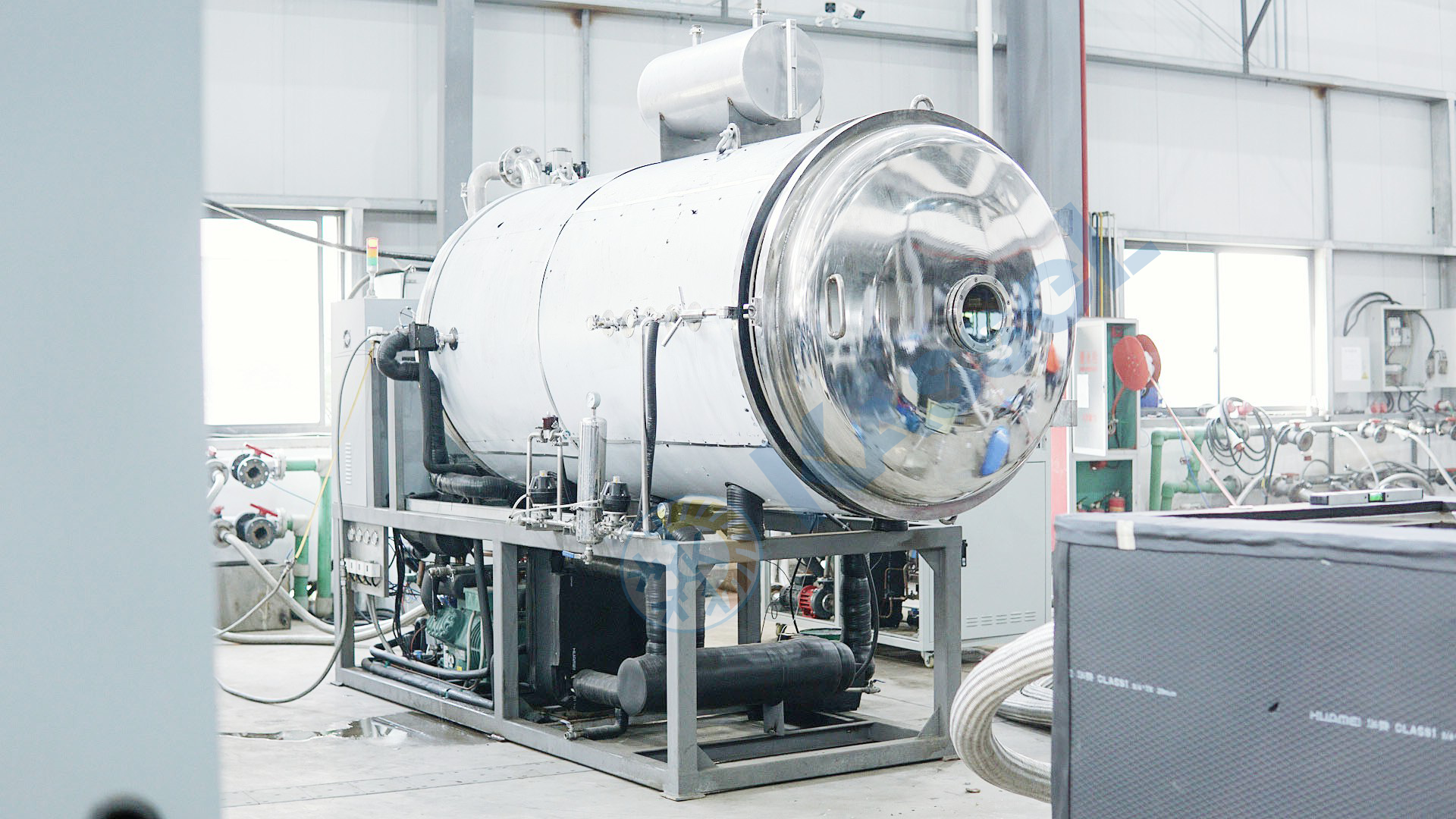

The food freeze dryer quickly freezes the water in fresh food into ice, and the food will be heated slowly in a vacuum freeze drying chamber to make freeze dried food.

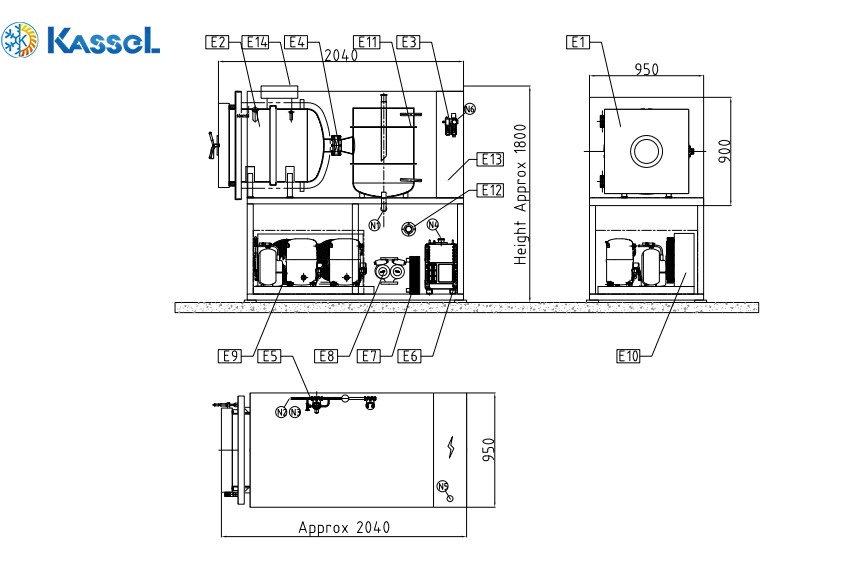

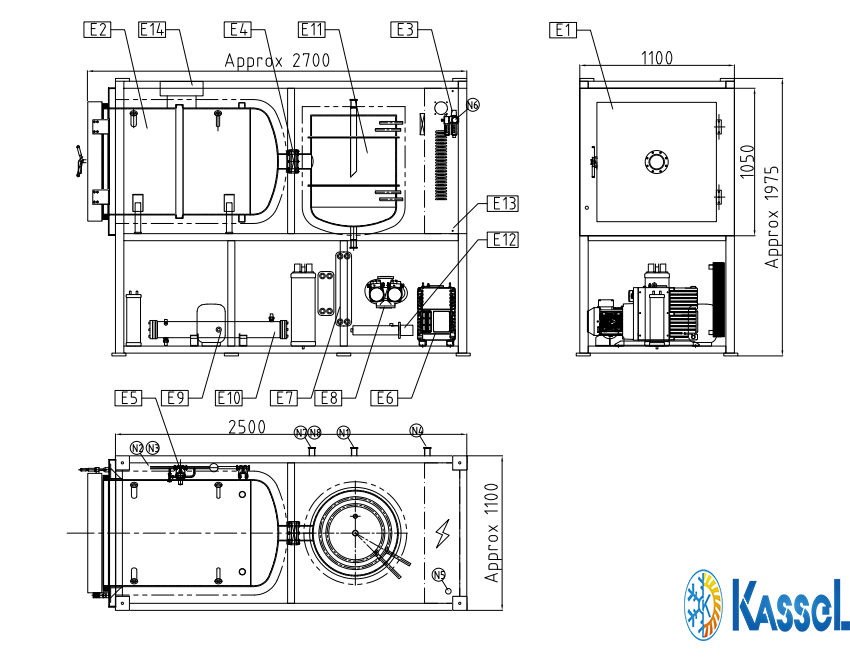

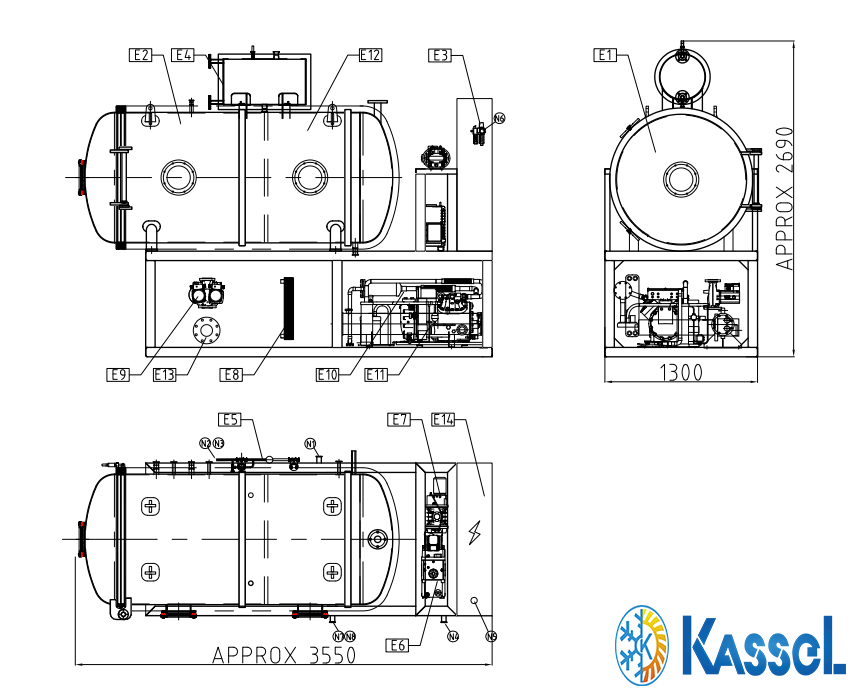

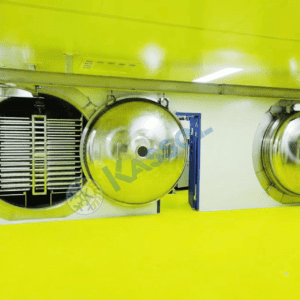

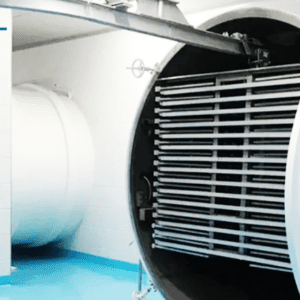

Food freeze-drying machine is composed of quick-freezing chamber, freeze-drying chamber, water trap, refrigeration system, vacuum system, heating system, electric control system, etc.KFD Freeze-dryer can meet the GMP standards, the equipment chamber, shelves, material tray are made of food grade stainless steel 304 or 316.

Quick-freezing chamber: Through the freezing equipment, the food will be rapidly frozen to -40 ℃ quickly by quick freezing chamber.

Vacuum Freeze-drying chamber: The frozen material is put in the vacuum freeze-drying chamber and heated slowly, the vacuum degree is about 10-20Pa and the temperature of heating is not more than 35℃, in the process of heating, the ice crystal in the material is changed from solid to water vapor (also called sublimation) to realize the process of dehydration.

Refrigeration System: The refrigeration system consists of a refrigeration compressor and auxiliary facilities to provide a cold source for the drying box and cold trap.KFD freeze dryer use German bitzer compressor, the compressor has good refrigeration effect, low energy consumption and good stability.

Vacuum system: the vacuum system consists of cold trap, vacuum pump, vacuum valve, vacuum measurement gauge etc.The vacuum pump is used to provide vacuum for the freeze drying chamber, so the water vapor can sublimate in this vacuum chamber, in addition, the vacuum pump can also form a vacuum pressure difference between the cold trap and the freeze drying chamber, so that the water vapor will be captured by the cold trap .KFD freeze dryer use german leybodl rotary vane pumps and Roots pumps , the vacuum system has fast pumping speed, high ultimate vacuum degree, low operation noise and good stability, in addition, it has good water removal ability.

Heating circulation system: Shelf cooling and heating are transfered by circulating medium (thermal oil or pure water), we use germany wilo water pump in circulating system to provide power for the whole heating circulating system, the pump is energy -saving , good stability ,low failure and easy maintenance.

Control system: The control system is used to control and regulate the temperature, pressure, humidity and time and other parameters in the whole freeze-drying process to ensure the stability and reliability of the freeze-drying process. KFD food freeze dryer use CE certified Germany Siemens control cabinet, Schneider electrical appliances, this system can monitor and regulate the freeze drying process accurately, to ensure the stability, reliability and safety of the freeze drying process, and improve the freeze drying effect and production efficiency.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Applications” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681968241190{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_video link=”https://youtu.be/uMsMA5HfO6A”][vc_column_text][/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_video link=”https://youtu.be/tlSSuV4Ljtg”][vc_column_text][/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Freeze Drying VS Drying” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1690784936903{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]1.foods are freeze-dried at low temperatue, without damaging their physical structure.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Applications” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681968241190{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_video link=”https://youtu.be/uMsMA5HfO6A”][vc_column_text][/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_video link=”https://youtu.be/tlSSuV4Ljtg”][vc_column_text][/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Freeze Drying VS Drying” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1690784936903{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]1.foods are freeze-dried at low temperatue, without damaging their physical structure.

2.Natural taste, color, shape ,nutritients and vitamins can be maintained, without any chemicals and additives.

3.Good rehydration performance when adding water.

4.Freeze-dried food is a healthier food

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Do you know the advantages of freeze drying technology?” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1690784971855{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Do you know the advantages of freeze drying technology?” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1690784971855{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Technical Specification” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681992318008{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_raw_html]JTVCd3BkYXRhdGFibGUlMjBpZCUzRDMlNUQ=[/vc_raw_html][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”How long does it take to freeze dry food?” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1690785261183{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]How long does it take to freeze dry food?

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Technical Specification” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681992318008{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_raw_html]JTVCd3BkYXRhdGFibGUlMjBpZCUzRDMlNUQ=[/vc_raw_html][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”How long does it take to freeze dry food?” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1690785261183{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]How long does it take to freeze dry food?

The freeze drying time is related with many factors, such as the type of food, its size, and its water content.

Water content of food: If the food has a lot of water, it will take more time to freeze dry. For example, it takes longer to freeze dry strawberries than blueberries.

Thickness and size of the food: If the foodis larger and thicker, it will take longer to freeze dry. Also more energy is consumed during the freeze drying process.

Therefore, from the point of saving energy and improving productivity, you can choose to cut the fruit into thinner and smaller shapes for freeze drying.

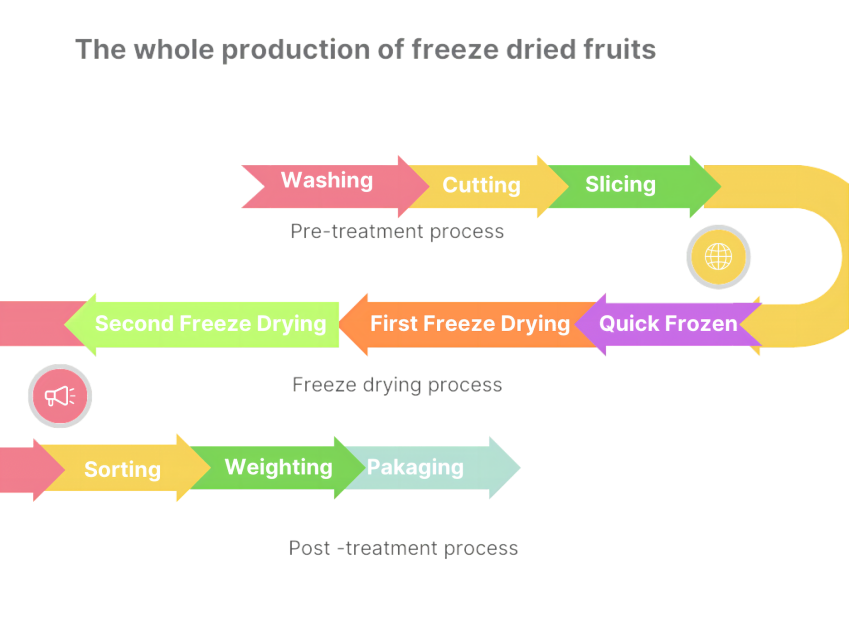

Generally speaking, the freeze-drying time for food is usually between 10~24h. For specific freeze-drying time, please contact Kassel, we will evaluate the material you need to freeze-dry and give you a more accurate freeze-drying time.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”What is the process of freeze drying?” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1690772951755{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]1.Product cleaning

2.Product peeling

3. Product slicing

4.Product loading: loading cut product into trays.

5. Product freezing: 2-3h get the product completely frozen in shortest time.

6.Vapor condenser freezing: 30min to catch vapor from sublimation

7.Vacuumize chamber: 30min ,to have an extremely low pressure.

8. Heating product: 8-15h, to speed up sublimation.

9. Unloading: 2min unload the final freeze dried product

10.Defrosting: 0.5~1h , defrost for next batch of production

11. Packing: Packing product avoid regain moisture.

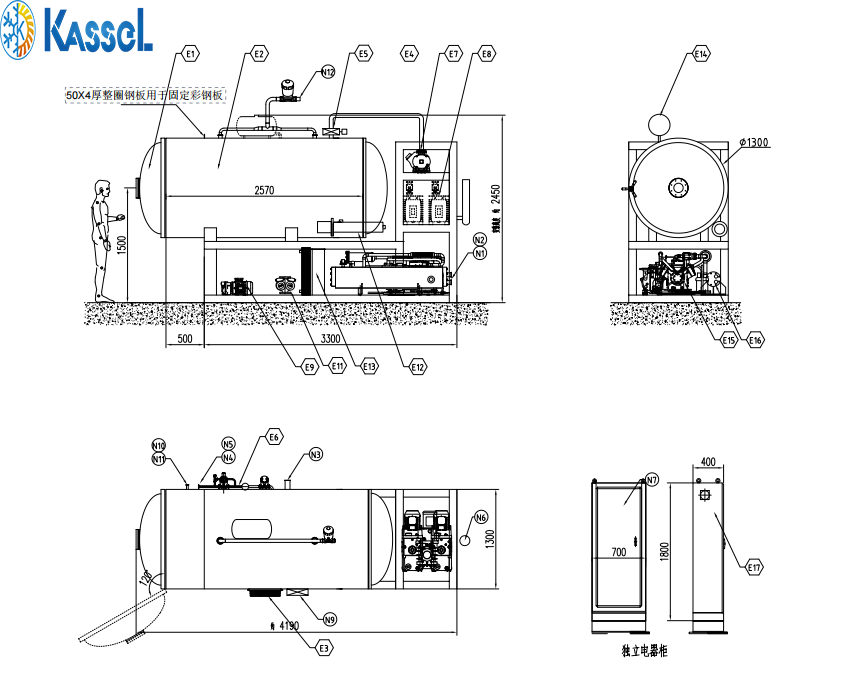

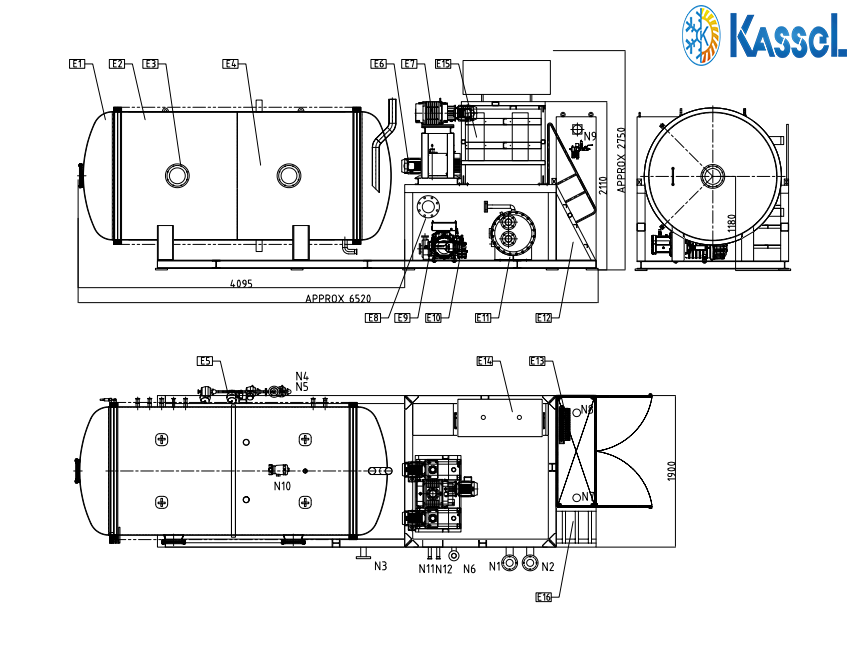

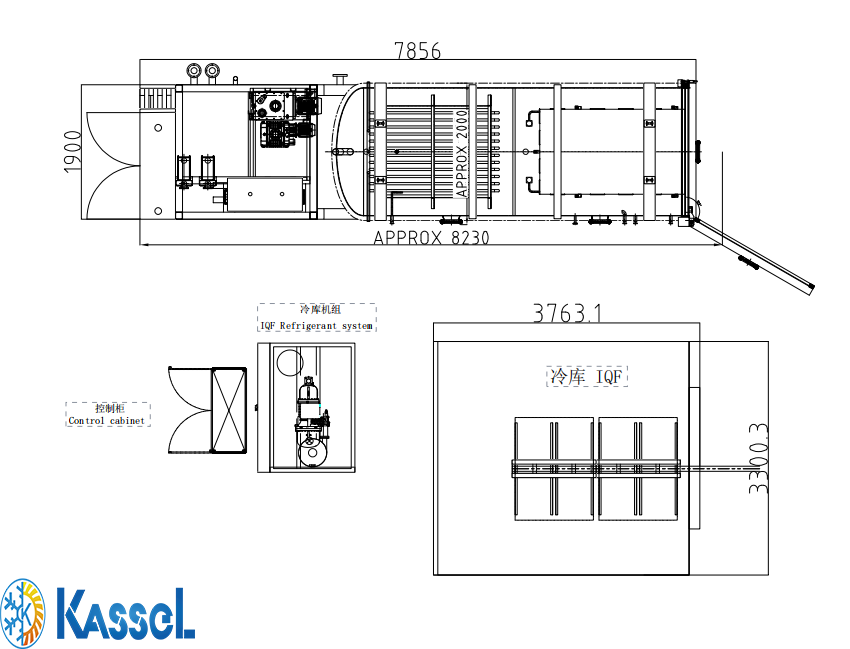

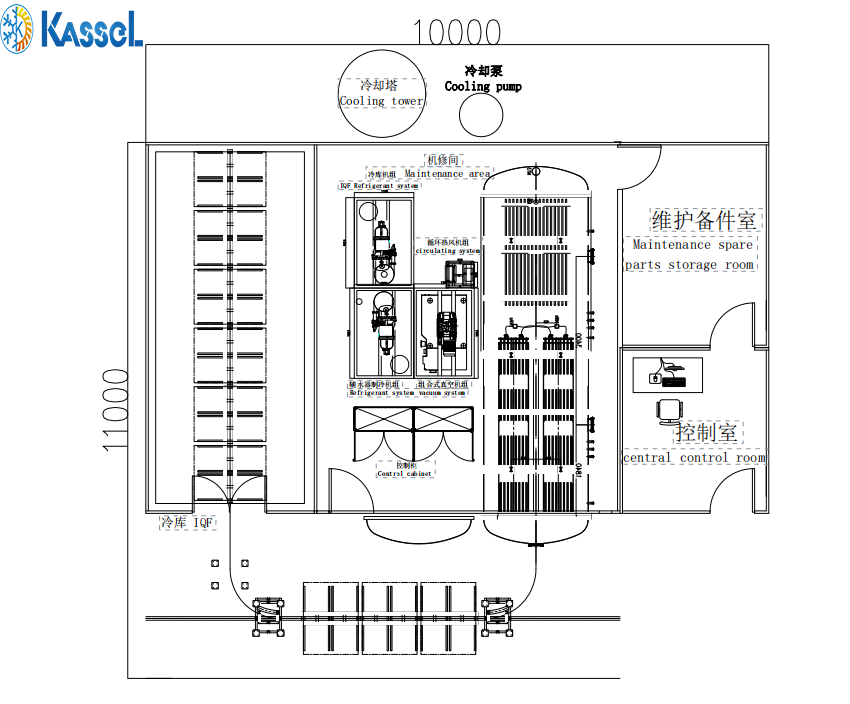

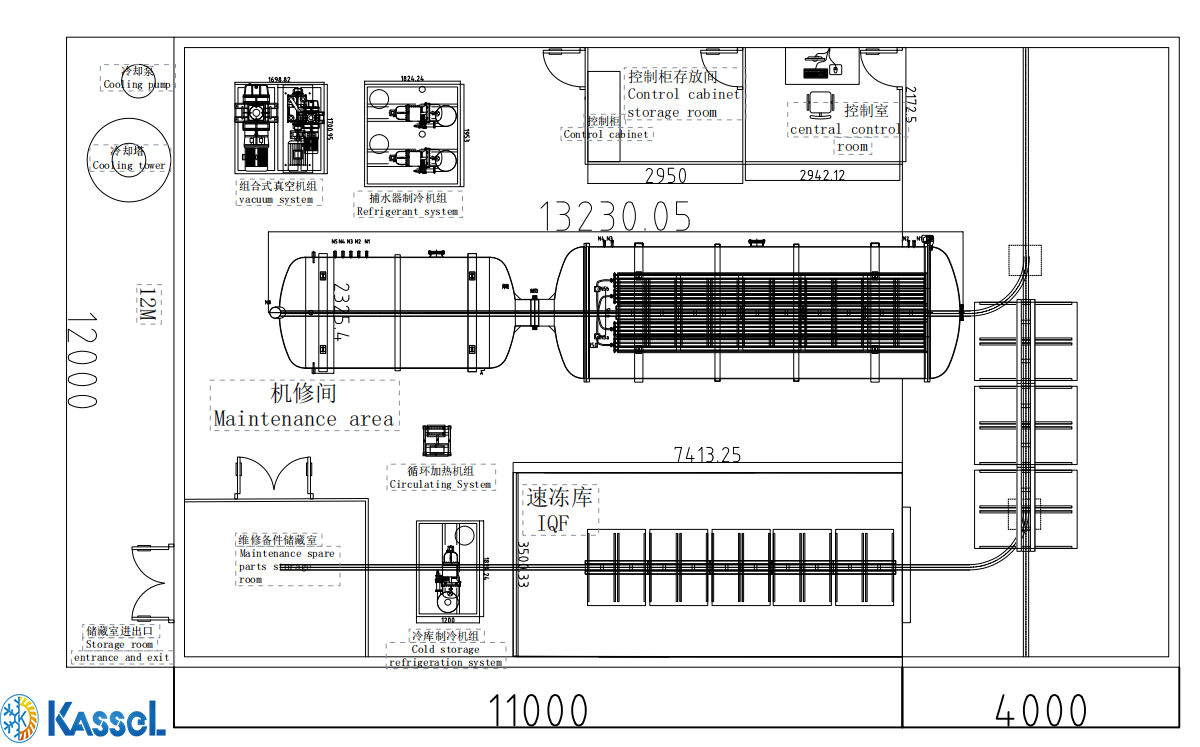

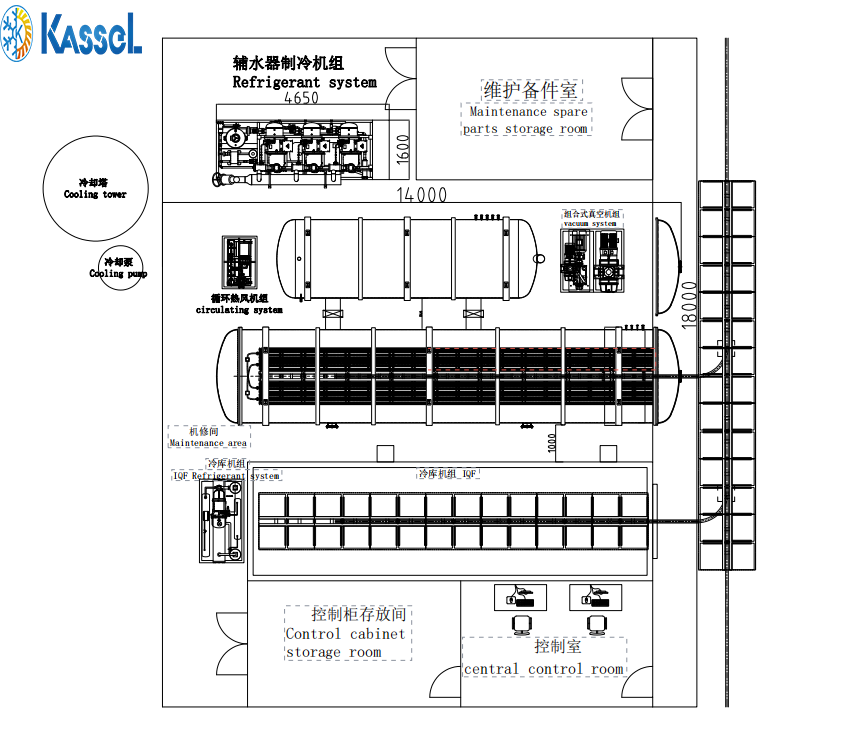

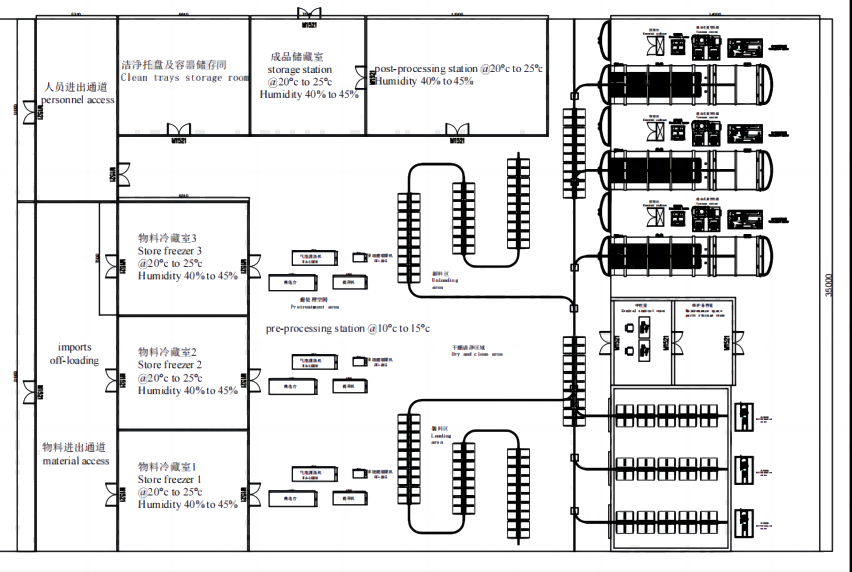

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Freeze Drying Workshop We designed for our customer” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1690539516571{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text]Kassel is a professional freeze dryer manufacturer, we can design a detailed freeze drying workshop layout for you according to the floor plan of your plant.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Freeze Drying Workshop We designed for our customer” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1690539516571{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text]Kassel is a professional freeze dryer manufacturer, we can design a detailed freeze drying workshop layout for you according to the floor plan of your plant.

In the design, we will consider the following factors:

1.The location of freeze dryer: According to your plant floor plan, we will determine the best location for the freeze dryerto ensure their smooth operation and easy maintenance and cleaning.

2.Workflow: We will reasonably arrange the equipment and work area in the freeze drying workshop according to your needs and process flow to improve productivity and work flow.

3.Space utilization: We will make full use of the space in the workshop to ensure that the layout of the equipment is compact and reasonable, and at the same time take into account the flow of personnel and safety.

4.Environmental requirements: According to the working characteristics and requirements of the freeze dryer, we will design appropriate ventilation system and environmental control equipment to ensure that the temperature, humidity and cleanliness in the workshop meet the requirements.

5. Safety Consideration: We will consider the safety factors in the design, such as the safety spacing between equipment and equipment, emergency stop device, etc., to ensure the safety of operators.

Please provide your plant floor plan and detailed requirements, we will design the layout according to your requirements and provide corresponding solutions.

[/vc_column_text][vc_custom_heading text=”Highlights And Features” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969791100{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]1.Aerospace grade aluminum alloy partition material, double-sided radiation heating, radiation rate of more than 90%, good temperature uniformity and thermal conductivity.

[/vc_column_text][vc_custom_heading text=”Highlights And Features” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969791100{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]1.Aerospace grade aluminum alloy partition material, double-sided radiation heating, radiation rate of more than 90%, good temperature uniformity and thermal conductivity.

2.High efficiency mixed refrigerant medium, low freezing point and high boiling point, high heat transfer efficiency, long service life

3.Patented gas diversion design and control technology, strong water capture ability, high drying efficiency.

4.Accurate sensor calibration function to ensure the accuracy of process parameters in long-term use.

5.The drying curve optimization control algorithm can control the heating rate and vacuum degree value of the products in the drying stage.

6.Bitzer compressor from germany, stable, reliable, no faluire.

7.Ulvac vacuum pump from japan, excellet performance ,no noise. good stability

8.Simens PLC control cabinet, safety, stable,effectiveness.

9.Perfect pre and after-sales service: providing instabllation, debugging,traing service etc

10.Pre-freezing and drying are two separated structures, which is able to freeze and dry at the same time. This can improve the efficiency of freeze-drying and product efficiency

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Successful Projects” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969204220{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Successful Projects” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969204220{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”How much is a freeze dryer machine?” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1690782540039{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]The price of a freeze dryer is related to a number of factors:

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”How much is a freeze dryer machine?” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1690782540039{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]The price of a freeze dryer is related to a number of factors:

- The model and capacity of the equipment: the larger the capacity of the freeze dryer, the higher the price; for example, the price of Kassel KFD-200 (which can process 2000 kg of fresh material at a time) is much more expensive than that of Kassel KFD10 (which can process 100 kg of fresh material at a time).

- Configuration: different manufacturers use different configurations, such as vacuum pumps, compressors, control cabinets, valves, etc., high-performance lyophilizers have higher configurations and higher prices.

- material and structure: the quality of the material and structure of the freeze dryer will also affect the price, high quality material and fine structure usually increase the cost.

- degree of automation: some lyophilizers have a higher degree of automation, such as automatic control systems, data logging and monitoring functions, etc. These features usually increase the price.

- Suppliers: Different suppliers use different technologies, production processes, and production experience, so the price of the machine will be different.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”FAQ” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1681969254779{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Why your price is relatively high?

We are in zhejiang province which is known for the quliaty of its mechanical manufacturing and fine craftsmanship. Our first priority is always based on the quality. If you want A more economica price,please let us know your budget, So that we could make some modification to meet your needs.

What is your installation service system?

Our enigneer has been working 20 years in freeze dryer machines and has been over to 20 countries to install our freeze dryer equipments. Now he has US Visa, So it is easy for him to go many other countries to start installation. So when we make a deal , we will arrange our engineer to your factory in 2 weeks, and he wil finish his work within 2 weeks. The customer should pay his round-trip ticket,hotel, food and daily wage USD100. Our engineer can speak english and can communicate with your team fluently . Excellent service deservces its cost.

What Is Your After-Sales Service System?

Our target customer groups are all from developed countries, USA, European, Middle east, Korea, Russia, Colomibia etc. They are all have high requirements with freeze-dryer. The core components of our freeze dryers are all imported from germany , Japan, Italy etc, has excellent stability , low energy consumption and almost no faluire. If there are any problems caused by non-human facors, we will undertake the full responsibility and relace new one for you, so please don’t worry about our after-sales service.

How Could You Control And Ensure Your Machine Quality?

Firstly of all, we are professional manufacturer and has own production line, the core components of freeze dryer are all imported from Germany, Japan,

Italy etc, and each part is completed independently by our factory self. We take the quality as priority and control the each production process strictly ,from design ,R&D, producing .We refuse to attract our customers with low price but low quality.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Send Inquiry” font_container=”tag:h4|text_align:left|color:%23ffffff” use_theme_fonts=”yes” css=”.vc_custom_1683357874324{padding-top: 15px !important;padding-bottom: 15px !important;padding-left: 15px !important;background-color: #0d66ae !important;}”]

[/vc_column][/vc_row]